Fire extinguishing technology with finely dispersed water. Modules of the TRV.

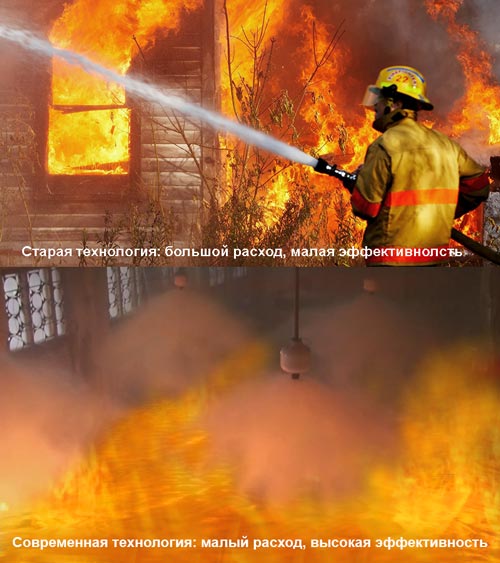

Fire extinguishing with finely dispersed water (TRV) is a modern, rapidly gaining popularity, highly effective fire extinguishing technology. As the extinguishing agent, water supplied under high pressure through special spray nozzles is used, due to which a fine mist is created out of drops of no more than 100-150 microns, which quickly fills the protected room. At the same time, a high efficiency of extinguishing fires with a minimum volume of consumed water is achieved, which makes it possible to apply the technology of TRV in modular fire-extinguishing systems.

The efficiency of fire extinguishing modules with finely dispersed water is achieved through the combined effect of the following factors:

- First, a water-dispersed fog has a high heat capacity and a large total area of the droplet surface, which leads to a rapid decrease in the temperature in the fire site and to the stopping of the chemical combustion reaction (the effect of reducing the temperature).

- Secondly, during the evaporation of water in the fire zone, a large amount of water vapor is formed which, being a gaseous substance, has the properties of voluminous fire extinguishing agents and penetrates into any gaps and porous surfaces, preventing the gas exchange of combustible materials with oxygen by reducing its concentration in the combustion zone (the effect of oxygen displacement).

- Thirdly, fine droplets of water and water vapor, depositing on the surface of materials not yet covered by the combustion process, creates a thin water film on their surface, preventing the fire from spreading to the adjacent area of the protected room (fire localization effect) adjacent to the fire area. In fire extinguishing modules with finely dispersed water, produced by MAPA “Eposos”, a foam-forming additive (potassium acetate) is used to enhance this effect. The solution of potassium acetate also prevents the freezing of water and allows the use of the TRV modules at low temperatures (up to minus 40 degrees Celsius)

Summarizing all of the above: the

fire extinguishing technology with finely dispersed water, in addition to cooling, implements two more extinguishing mechanisms – isolation of the focus and reduction of the oxygen concentration.

There is another undeniable advantage of the fire extinguishing modules of the TRV in front of other means of fire protection – absolute environmental friendliness and safety for humans. This makes it possible to apply this technology to living quarters, shopping pavilions, industrial workshops and other premises with the presence of people. Rapid spray of water mist and its instantaneous cooling effect allows evacuation of indoors people even during the active phase of the fire (when the fire extinguishing system is activated).

In addition, fine-water has a unique ability to precipitate smoke. The practice of application shows that immediately after the activation of the fire extinguishing modules of the TRV there is no need to switch on the ventilation system to remove the smoke.

The principle of operation of fire extinguishing modules with finely dispersed water.

The principle of operation of the TRV modules is as follows:

1. The sensors of the automatic fire extinguishing system detect a fire, after which the system issues an electrical signal for the start of the fire suppression modules.

2. The gas generator of the fire extinguishing module triggers from the incoming electrical pulse, which releases an inert gas into the internal cavity of the module, which leads to a rapid increase in pressure inside the module housing.

3. When the critical pressure in the body is reached (the process takes place in a fraction of a second), the safety membrane of the TRV module collapses and the water is discharged through the fine spray to the protected room.

It should be noted that in the passive state (before operation), the pressure inside the module housing is completely absent, which significantly reduces the possibility of loss of its operability as a result of slight depressurization and gradual bleeding of pressure. This advantageously distinguishes modules with the gas-generator principle of operation from other systems that are constantly under pressure.